The shops are already full of jerseys and heaters to get you ready for winter. But, is your plant, factory and staff prepared for the upcoming cold months?

eltherm South Africa recognizes that colder ambient temperatures can wreak havoc on your manufacturing processes and operational efficiencies, which can cause downtime and affect your bottom line.

Electrical heat tracing lowers the viscosity of many processes as it acts as a compensating heat source to maintain or raise the heat in pipes, tanks, surfaces and other vessels. It effectively replaces the heat loss in the process and can therefore be used to prevent pipes from gelling or freezing, whilst maintaining the low viscosity of the process on plant equipment.

No one wants to have a plant shutting down due to poor planning and maintenance.

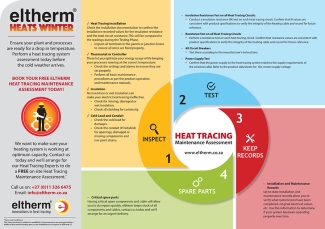

To help you check your heating system,  we’ve drawn up this handy infographic which you can download right now. It will help you plan ahead and decide whether or not you need one of our qualified eltherm engineers to do a site visit and ensure your heat tracing system is operating at its maximum capacity.

we’ve drawn up this handy infographic which you can download right now. It will help you plan ahead and decide whether or not you need one of our qualified eltherm engineers to do a site visit and ensure your heat tracing system is operating at its maximum capacity.